Publication: SCF 2025 “Robotically Produced Timber Dowel Double-Curvature Discrete Shell” B.Bagheri, S.Mostafavi, E. Montejano, M.Segovia, C.Scott, U.Lee

Top view of the fully assembled pavilion(curvature discrete shell).

Integrated Computational Design to Augmented Production of a Dry-Assembled Pavilion Structure

Paper Published in SCF 2025 - MIT

The paper titled

“Robotically Produced Timber Dowel Double-Curvature Discrete Shell ”

authored by Bahar Bagheri, Sina Mostafavi, Edgar Montejano Hernandez, Mark Segovia, Caleb Scott, and Uijin Lee, has been published in the proceedings of SCF 2025, part of the Proceedings of the ACM Symposium on Computational Fabrication held November 20–21, 2025, in Cambridge, MA, USA..

Project Summary

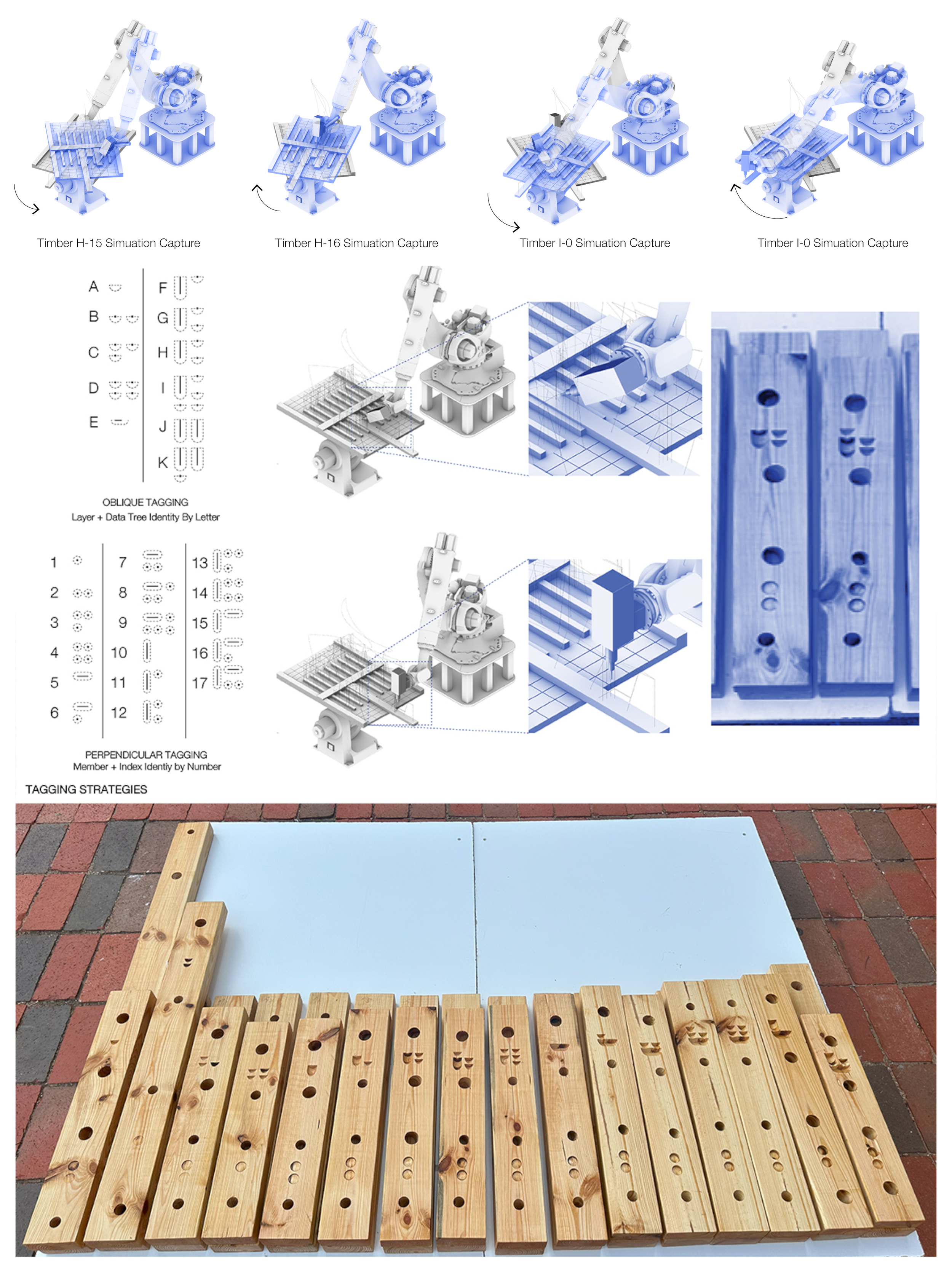

This paper presents the development and realization of a double‑curvature timber discrete shell built with a dry‑assembled, dowel‑joined system and an integrated pipeline that combines computational design, parametric structural analysis, multi‑axis robotic milling, and augmented‑reality‑guided production and assembly. An iterative macro‑to‑micro workflow enables form‑finding, aligning architectural geometry with structural performance, fabrication precision, and assembly logic. Adaptive tessellation—implemented through a recursive method that respects the constraints and potentials of timber‑dowel connections—divides the surface into a mesh of non‑convex octagons, from which discrete timber components of varied length, thickness, and joint orientation are derived. Iterative parametric structural simulations across multiple joint‑and‑support degree‑of‑freedom configurations steer material allocation and inform timber and dowel distribution. A 7‑axis robotic milling setup delivers accurate fabrication of these non‑repetitive geometries while avoiding kinematic singularities; on‑site assembly is streamlined by spatially aligned holographic guidance, eliminating reliance on conventional drawings, and a tertiary locking pin prevents dowel rotation to secure each joint. The process culminates in a full‑scale pavilion comprising 181 unique timber members and 330 hardwood dowels, demonstrating a data‑ and resource‑driven design‑to‑production workflow for scalable timber construction. Following these results, the paper concludes by outlining future work on multi‑actor human–robot collaborative assembly processes for timber construction, with an emphasis on design for assembly and disassembly at larger scales.

Academic Context & Collaboration

This research has greatly benefited from the dedication and support of the faculty, researchers, staff, and students at TTU HCoA and the Hi-DARS lab team. The design-to-production and analysis methods were initially developed by members of the Hi-DARS lab team at TTU and further explored and tested by graduate students as part of the Spring 2024 ARCH 5334 course:(Advanced Architectural Technology I) instructed by Sina Mostafavi, with assistance from Research and Teaching Assistants: Cole Howell (SA), Brodey Myers (TA), Edgar Montejano (GRA), and Bahar Bagheri (GRA). The core computational design and augmented robotic fabrication methods presented in this research were further developed collaboratively by B. Bagheri, E. Montejano, C. Howell, and S. Mostafavi, each contributing to different aspects of the system. External collaborators, including members of the SPFB, provided additional input and support. The methods were further developed and explored as part of ARCH 5301 in Spring 2025 with the following students: Brian Arellano, Luiz Trujillo, Enrique Espinoza, Jakelin Silva, Caleb Scott, Amanda Gomez, Mark Segovia, Mahamat Adoum Hassane, and Kathleen Gutierrez. Additionally, we gratefully acknowledge the assistance of Hussam AlHaj, Jose Gutierrez, and Uijin Lee in supporting the AR assembly process. In Summer 2025, further research development and graduate and student assistantships for Uijin Lee, Mark Segovia, and Jose Gutierrez were supported through the NSF ReDDDoT program, Phase 1: Planning Grant: Building Community-Driven Resilience and Empowerment through Adaptive Manufacturing Technologies (Award Abstract #2427747).

The computational and augmented fabrication methods were further developed by Bahar Bagheri, Sina Mostafavi, and Edgar Montejano, each contributing to specific layers of the system.

Future work will also focus on testing the JRL system at different scales, including one-to-one fabrication and load-bearing tests of optimized timber-dowel reciprocal lattice systems.

🔗 Read the Abstract (SCF 2025)

#SCF2025 #HiDARS #TexasTechArchitecture #ComputationalDesign #RoboticFabrication#AugmentedReality#DigitalFabrication#DesignToProduction #ParametricDesign#GenerativeDesign#ArchitecturalComputing#TimberArchitecture#TimberConstruction#DesignForAssembly

#MIT#ACMSCF#ComputationalFabrication#ResearchPublication#ArchitectureResearch#DesignForDisassembly

Abstract

This paper presents the development and realization of a double‑curvature timber discrete shell built with a dry‑assembled, dowel‑joined system and an integrated pipeline that combines computational design, parametric structural analysis, multi‑axis robotic milling, and augmented‑reality‑guided production and assembly. An iterative macro‑to‑micro workflow enables form‑finding, aligning architectural geometry with structural performance, fabrication precision, and assembly logic. Adaptive tessellation—implemented through a recursive method that respects the constraints and potentials of timber‑dowel connections—divides the surface into a mesh of non‑convex octagons, from which discrete timber components of varied length, thickness, and joint orientation are derived. Iterative parametric structural simulations across multiple joint‑and‑support degree‑of‑freedom configurations steer material allocation and inform timber and dowel distribution. A 7‑axis robotic milling setup delivers accuracy fabrication of these non‑repetitive geometries while avoiding kinematic singularities; on‑site assembly is streamlined by spatially aligned holographic guidance, eliminating reliance on conventional drawings, and a tertiary locking pin prevents dowel rotation to secure each joint. The process culminates in a full‑scale pavilion comprising 181 unique timber members and 330 hardwood dowels, demonstrating a data‑ and resource‑driven design‑to‑production workflow for scalable timber construction. Following these results, the paper concludes by outlining future work on multi‑actor human–robot collaborative assembly processes for timber construction, with an emphasis on design for assembly and disassembly at larger scales.