Tokyo, CAADRIA 2025 | S. Mostafavi, B. Bagheri, C. Scott, E. Montejano, C. Howell, & A. Published Integrated Computational Design to Augmented Production of Timber-Dowel Structures

Integrated Computational Design of Free Form Shell Structures Using Timber-Dowel System

Integrated Computational Design to Augmented Production of Timber-Dowel Structures

Paper Published in CAADRIA 2025 Proceedings – Tokyo

The paper titled

“Integrated Computational Design to Augmented Production of Timber-Dowel Structures: A Multi-Criteria System for Informed Variation and Community Co-Production”

authored by Sina Mostafavi, Bahar Bagheri, Caleb Scott, Edgar Montejano Hernandez, Cole Howell, and Asma Mehan, has been published in the proceedings of CAADRIA 2025, part of the Architectural Informatics Conference held March 22–29, 2025, in Tokyo, Japan.

Project Summary

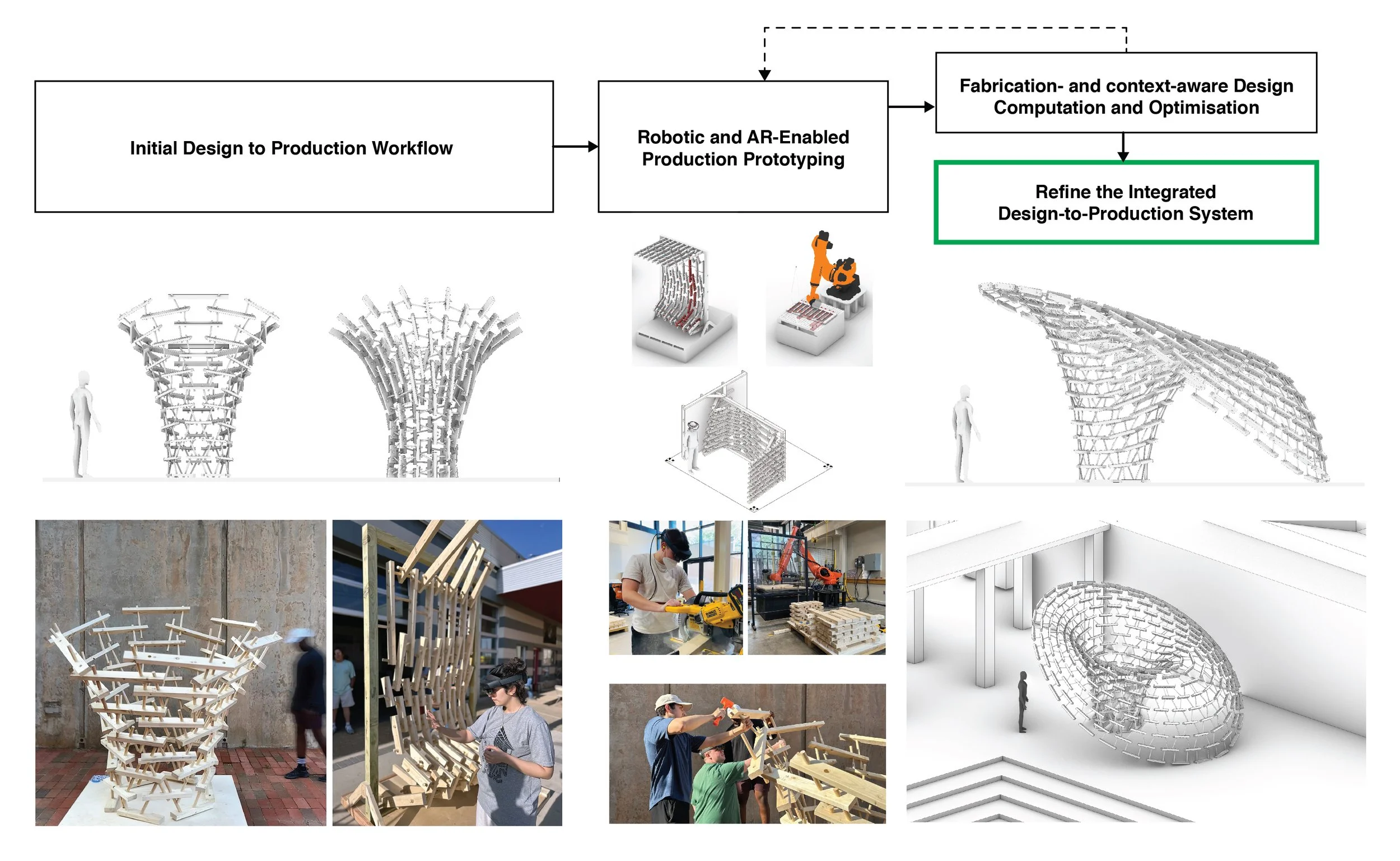

This research introduces a computational design-to-production framework for timber-dowel structures, integrating robotic milling, AR-guided assembly, and parametric design methods to support informed variation and collaborative workflows. Two full-scale prototypes—developed and tested with feedback loops from fabrication and community use—serve as the foundation for a multi-criteria system balancing structural integrity, production constraints, and contextual adaptability. The project emphasizes horizontal configurations for inherent stability and evaluates geometric variations for performance-based design.

Academic Context & Collaboration

The research was developed as part of an ongoing body of work at the Hi-DARS Lab (Hybrid Intelligence Design and Architectural Robotic Systems Lab) at the Huckabee College of Architecture, Texas Tech University, initiated in the Spring 2024 ARCH 5334: Advanced Architectural Technology I course taught by Dr. Sina Mostafavi.

Two core studio experiments—Landscape + Canopy and Oven + Canopy—formed the foundation for full-scale prototype development, driven by graduate student teams and supported by Cole Howell (RA), Edgar Montejano (GRA), Bahar Bagheri (GRA), and Brodey Myers (TA).

The computational and augmented fabrication methods were further developed by Bahar Bagheri, Sina Mostafavi, Edgar Montejano, and Caleb Scott, each contributing to specific layers of the system. Concurrently, Dr. Asma Mehan led the Community Design and Development Resources (ARCH 5384) seminar, providing key contextual framing that informed the project’s community-centered co-production logic.

Collaborative input from South Plains Food Bank members and TTU HCoA faculty further reinforced the applied, resource-sensitive focus of the study.

🔗 Read the full paper (CUMINCAD)

#CAADRIA2025 #HiDARS #TexasTechArchitecture #TimberDowelStructures #ComputationalDesign #RoboticWood #ARAssembly #AugmentedFabrication #CoProduction #CircularConstruction #ArchitectureResearch

Abstract. This research explores the design-to-production computational framework of a Timber Dowel System, emphasizing an integrated computational workflow informed by fabrication and assembly feedback. This workflow incorporates contextual and fabricability parameters, enabling a parametric framework optimized for performance, adaptability, and scalability. The initial design process utilized a modular plug-and-play approach, employing manually controlled surfaces and poly-surfaces to explore flexible geometries and structural configurations. Two full-scale prototypes were developed using AR-guided assembly and robotic milling, addressing production challenges such as dowel placement precision, material limitations, and assembly feasibility. Feedback from these prototypes informed refinements in the computational framework, translating into practical parameters to improve structural integrity and procedural efficiency. A horizontal orientation was prioritized due to its standalone stability, while multiple extensions of the initial basket prototype were analysed to evaluate and study the system's performance under varied geometric configurations. By integrating community-driven requirements and contextual considerations, this research lays the groundwork for a multi-criteria framework that supports informed design variation and facilitates collaborative co-production workflows.

Keywords. Timber-Dowel Structures, Augmented Fabrication, Adaptive Tessellation, Data-driven Design, Robotic Wood fabrication

Acknowledgements

This research has greatly benefited from the dedication and support of the faculty, researchers, staff, and students at TTU HCoA and the Hi-DARS lab team. The design-to-production and analysis methods were initially developed by the HiDARS lab team members at TTU and further explored and tested by graduate students as part of the Spring 2024 ARCH 5334 course, Advanced Architectural Technology I, instructed by Sina Mostafavi. Two key projects form the foundation for exploration: Landscape + Canopy (Brandon Paleo, Garrett Whitehead, Gunner Murrell, Jack Dittrich, Jacklyn Hurtado, Jakelin Silva, Kathleen Gutierrez, Max Halwas) and Oven + Canopy (Aaron Malavolta, Amanda Gomez, Apollo Nyoma, Caleb Scott, Gabe Herrera, Harmony Smith, Mattia Hajmeli, Robin Mutchler), with assistance from Research and Teaching 405 S. MOSTAFAVI ET AL. Assistants: Cole Howell (RA), Brodey Myers (TA), Edgar Montejano (GRA), and Bahar Bagheri (GRA). The core computational and augmented fabrication methods presented in this research were further developed collaboratively by B. Bagheri, S. Mostafavi, E. Montejano, and C. Scott, each contributing to different aspects of the system. Additionally, Asma Mehan conducted a parallel joint seminar on Community Design and Development Resources (ARCH 5384) in Spring 2024 at TTU, which conceptually and contextually contributed to the framework of the presented project. External collaborators, including members of the SPFB, provided additional input and support.