Z Brick Wall - AR Assembly

The “z” brick wall project integrates AR-enabled assembly processes with digital fabrication techniques, utilizing reclaimed materials to create a flexible and modular system. This project is part of a study exploring the expanded possibilities of circular construction through the use of non-standard materials. By employing AR-assisted cutting and assembly techniques, this project demonstrates how reclaimed wood can be transformed into a new type of modular brick with interlocking capabilities, redefining architectural possibilities.

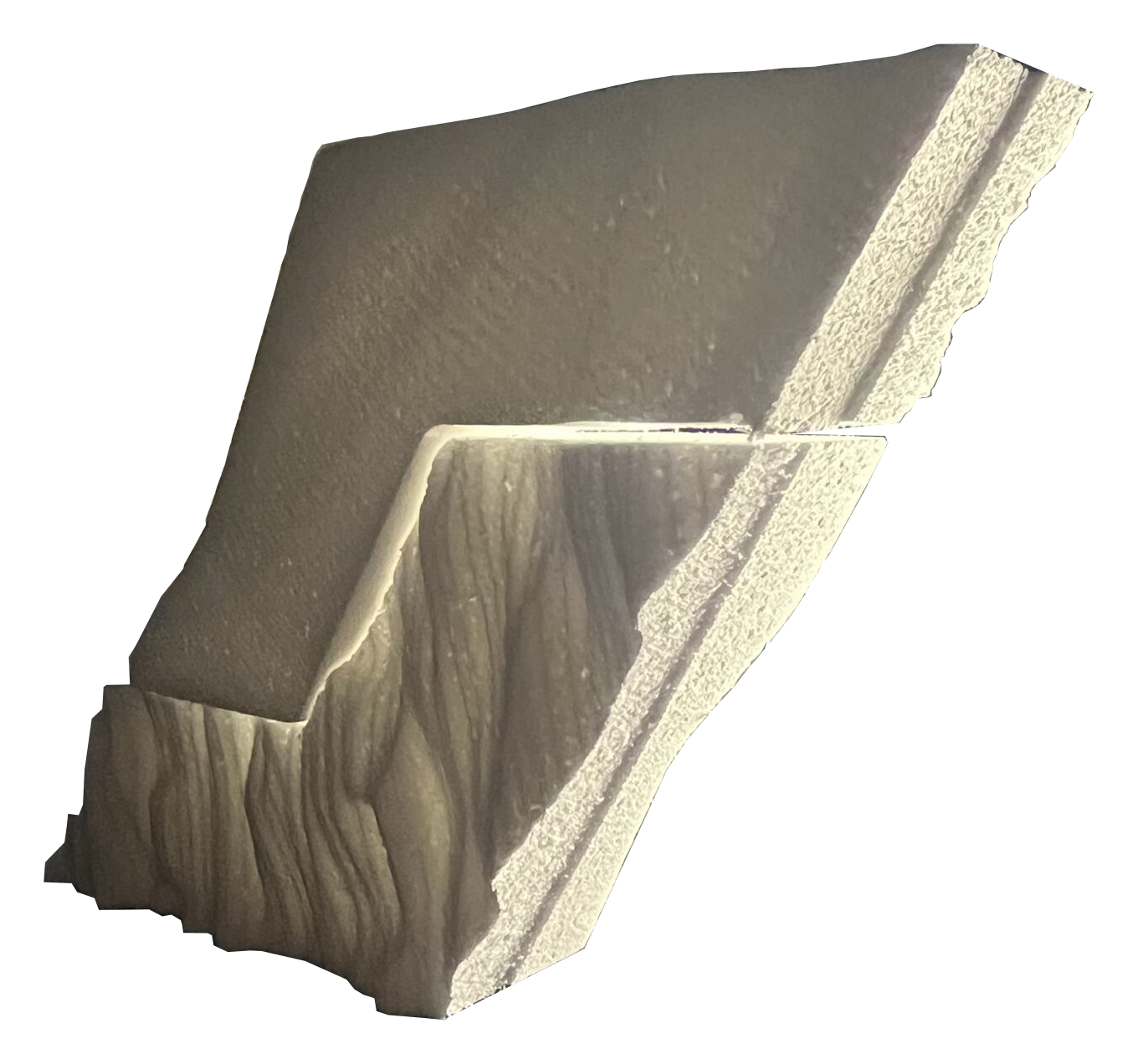

The modular system is designed to be highly adaptable and scalable for various urban applications. It uses reclaimed 2x4 wooden elements, which are cut into small pieces at a 45-degree angle along their width, forming "Z" bricks. This unique Z brick configuration enhances the precision, efficiency, and accuracy of the assembly process, using a guide system that facilitates quick and precise construction. The tapered edges of the wooden bricks increase the compact surface area, allowing for better assembly and greater flexibility in terms of form curvature.

The system emphasizes the use of local and recycled materials, promoting circularity in urban design. By focusing on resourcefulness, the brick wall seeks to minimize environmental impact while maximizing design potential. The modular nature of the wall system allows it to adapt to different forms, offering designers the ability to explore variations in porosity and other architectural possibilities in both urban and remote settings.

INFO | CREDITS

Hi-DARS lab Core Team:

Principal: Associate Prof. Dr. Sina Mostafavi

Graduate Research Assistants: Edgar Montejano, Cole Howell, Bahar Bagheri

Participants: Alexander Garza, David Nelson, Chance Welles, Jakob Wiesner

TTU HCoA Course:

Fall 2023 | Arch 5354 TTU-Adv. Arch. Tech.

Integrated Design to Robotic Production and AR-enabled Assembly Processes

Authors of this Page: Sina Mostafavi, Bahar Bagheri, Edgar Montejano Hernandez