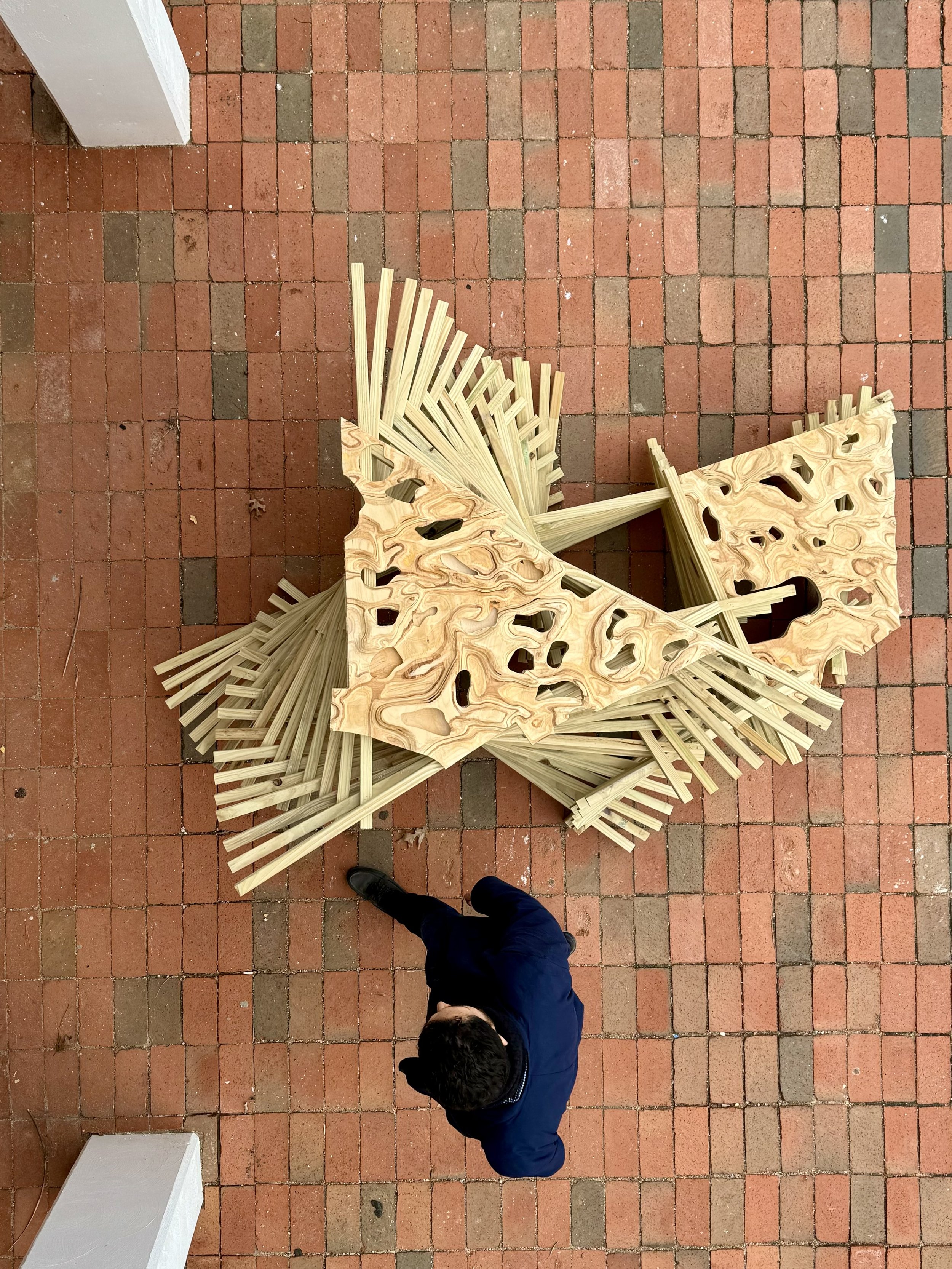

Helical Bench - AR Assembly

The helical bench project highlights the integration of AR-enabled production processes and digital fabrication techniques with reclaimed materials. The helical bench is part of a broader study exploring augmented production methods in the context of circular construction and regenerative design. By incorporating AR and digital fabrication, including robotic milling and the use of reclaimed wood, this project showcases the expanded possibilities in construction using non-standard materials. The design and assembly of the bench were developed as part of an augmented fabrication workflow tailored to the specific characteristics of the reclaimed wood, demonstrating the potential of circular construction practices.

The project is a piece of urban furniture designed to be adaptable, circular, and personalized. The bench leverages Augmented Reality (AR) to allow real-time customization and updates. It utilizes reclaimed two-by-two wood pieces, which are cut into five different lengths to minimize waste. A systematic approach has been developed to maximize the number of pieces obtained from each wood element. These pieces are then strategically stacked next to the assembly area for easy access during the construction process.

The bench is a functional seating solution that integrates technologies such as AI, robotic fabrication, and digital fabrication. Generative AI and diffusion models were employed to create organic, sponge-like textures on the wood surfaces. These textures serve both an aesthetic purpose and a functional one, as they are designed to support the growth of mycelium or moss, allowing the bench to blend seamlessly into its environment. The construction of the bench involves stacking these modified wood elements to form the structure, with the organic surfaces used for seating and tables. The assembly process is guided by an AR digital twin, which ensures precision in placing each piece from the bottom layer to the top.

INFO | CREDITS

Hi-DARS lab Core Team:

Principal: Associate Prof. Dr. Sina Mostafavi

Graduate Research Assistants: Edgar Montejano, Cole Howell, Bahar Bagheri

Participants:

Timothy Tipparach, Timothy Estrada, Tyler Glass, Thomas Mindheim

TTU HCoA Course:

Fall 2023 | Arch 5354 TTU-Adv. Arch. Tech.

Integrated Design to Robotic Production and AR-enabled Assembly Processes

Authors of this Page: Sina Mostafavi, Bahar Bagheri, Edgar Montejano Hernandez